Espresso Machine Boiler Materials Guide

Updated for 2021

Overview

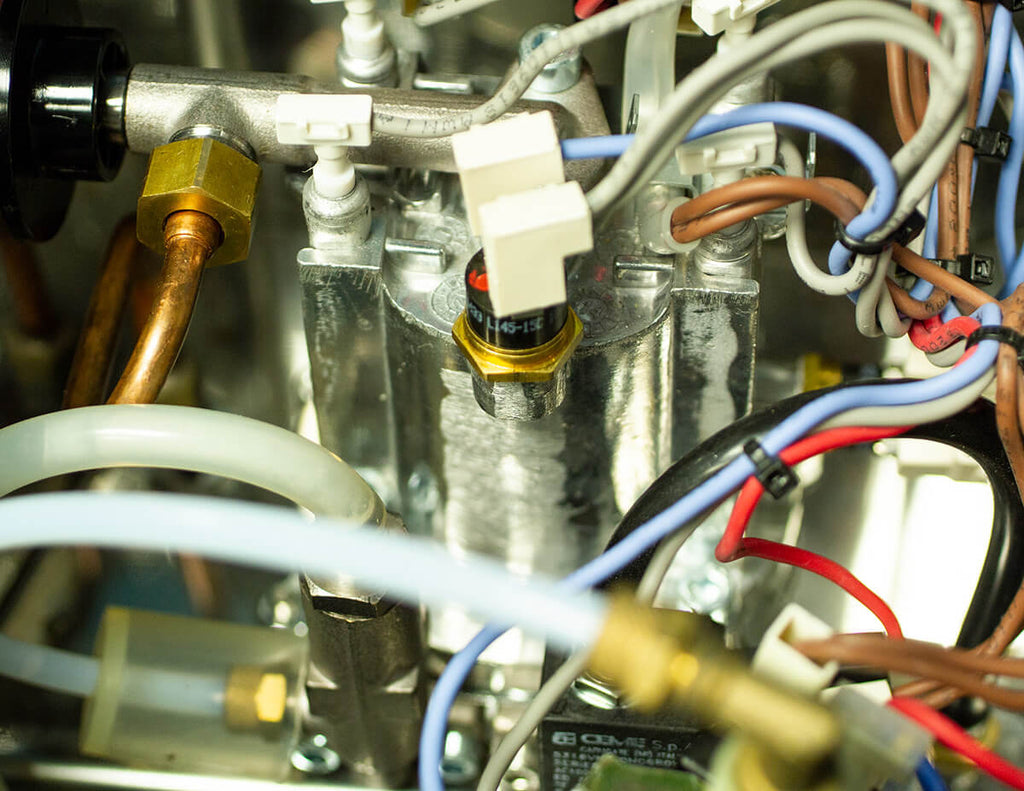

Boilers for the modern espresso machine speak to their purpose through the materials used to construct them. These materials are varied, and sometimes a combination of materials are used when boilers are manufactured. The composition of a boiler should be strongly considered, but it is hard to say exactly when one one material is better than the other. The key point is that when the manufacturer designs an espresso machine, they take into consideration how they want the machine to operate, and then pick the materials they want to use. Sometime cost is a consideration in their decision and sometimes it is not.

Aluminum

Aluminum is a metal more commonly found in small espresso machines, owing to its lower cost, light weight, and fair resistance to corrosion. The Gaggia Classic famously uses aluminum in its boiler for the model sold in the United States. With the Classic the boiler the heating elements are on the outside of the boiler so they won’t burn out to the boiler being low on water and it heats up very quickly. Its thermal conductivity is quite high, though not as high as copper.

Attributes

- Second best thermal conductor (after copper).

- Less expensive than copper.

Stainless Steel Lining

In order to improve its corrosion resistance, some manufacturers choose to line their thermoblock aluminum boilers with a layer of stainless steel. This is commonly done to marry the high resistance of the steel with the natural rapid heating of the aluminum.

Stainless steel tubing is run through the aluminum thermo block so the water never comes in contact with the aluminum.

Popular Machines with Aluminum Boilers

- Gaggia Classic

- All super automatic machines have aluminum thermoblocks with a stainless steel water lines running through them.

Brass

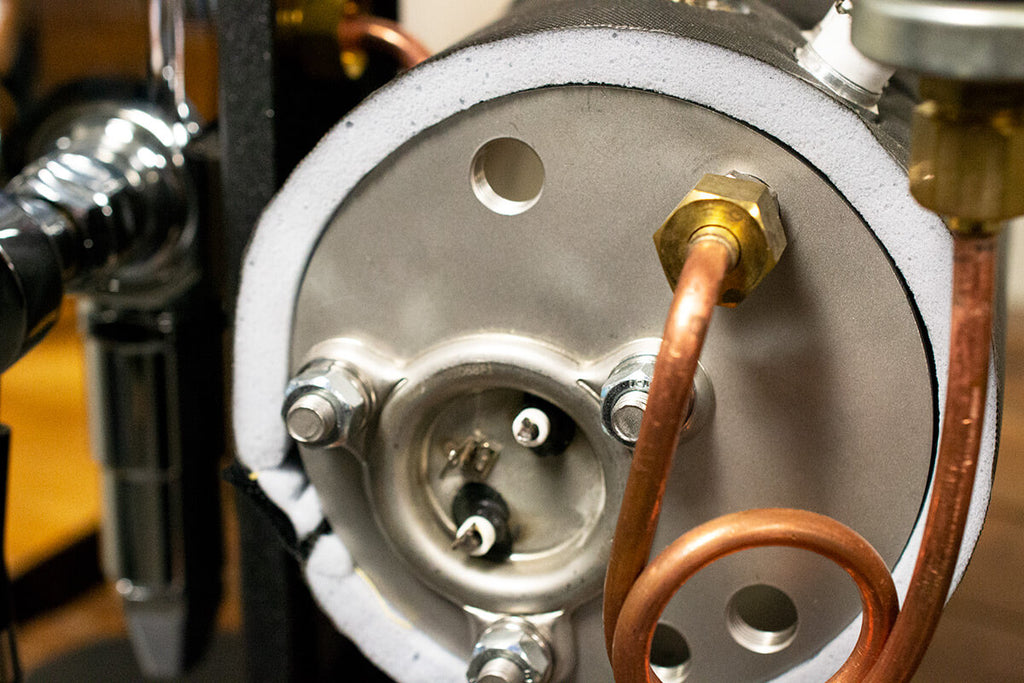

Brass is an alloy composed primarily of copper and zinc. Because zinc is cheaper than copper, brass in general is a less expensive metal and found in smaller machines or used to save money. The zinc content in brass will impact its thermal properties with a content of 32 - 39% increasing its hot-working abilities. Brass is used in the boiler end plates of many high end and commercial machines because it works as an excellent metal to cut threads into for attaching screwed fittings.

Attributes

- Lower thermal conductivity than aluminum or copper, but greater than stainless steel.

- Less expensive than copper.

- Easy for manufacturers to work with.

Eco Brass

A variety of lead-free brass called Eco Brass is used by ECM in the construction of their machines to assuage any fear of lead contamination in the brass.

Nickel Plating

In order to increase its resistance to corrosion, some manufacturers employ nickel plating in order to better protect the boilers in their machines. The nickel creates a barrier between the brass and any potential corrosive substances that enter the boiler. It also protects against any leaching of chemicals from the boiler to the water.

Popular Machines with Brass Boilers

Copper

Copper is a very commonly used metal for the construction of espresso machine boilers. It is good at conducting and retaining heat, making it an ideal choice for heating water. This is also why copper is popular in cookware as well. Copper is also commonly used in plumbing, as it is known for its antimicrobial properties, again making it a good choice for boilers.

For practical purposes, copper boilers are fitted with brass endplates in order to allow pipes and other components to be drilled into or run through them.

In general, copper is more expensive than aluminum, brass, and stainless steel, so its inclusion in an espresso machine may contribute to a higher price point.

Attributes

- Best thermal conductor

- Most expensive (pricier than aluminum, brass, and steel)

- Antimicrobial properties

- Less resistant to corrosion than stainless steel

- Flexible and can endure mechanical stress

Popular Machines with Copper Boilers

- ECM Technika IV

- Expobar Pulser, Expobar Control, Expobar Lever, Expobar Brewtus

- Profitec Pro 800

- Rocket Espresso Giotto, Rocket Espresso Mozzafiato, Rocket Espresso R58

- 969.Coffee Elba 1/3

Stainless Steel

Stainless steel boilers are widely used across a broad spectrum of machines. The relatively low cost of stainless steel, coupled with its durability and corrosion resistance make it a solid choice for boiler construction. Compared to other boiler metals, stainless has a lower conductivity, but it makes up for this by requiring less material to be used.

Attributes

- Highest resistance to corrosion

- Affordable and durable metal

Popular Machines with Stainless Steel Boilers

- ECM Classika PID, ECM Technika, ECM Mechanika IV Profi, ECM Elektronika II, ECM Synchronika

- Profitec Pro 500 PID, Profitec Pro 700

Insulation

Some boilers we sell are insulated by the manufacturer. The material used for the insulation can vary, but its function is always the same. Insulation helps the boilers to retain heat. Espresso machines use thermostats, pressurestats, and PIDs in order to monitor boiler temperature. When it drops below a certain threshold, power is sent to a heating element to bring it back up. Insulated boilers radiate less heat, meaning that less energy needs to be expended to keep them hot.

The secondary benefit of insulating the boiler is that the machine’s internal components are shielded from some of the heat that is given off by the boiler.

Canada

Canada